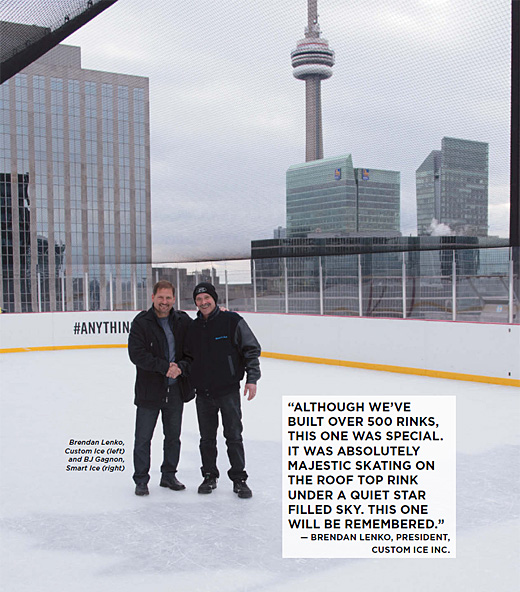

Rink on the roof

By: Brendan lenko, p.eng.

april 11, 2016

After a successful 2015 marketing

program featuring

a natural ice rink

in the middle of the

Rocky Mountains,

Molson went to new

heights for its 2016

“Anything for Hockey” campaign. This

time they decided to put a rink on the

roof of a Toronto skyscraper. To build

this rink they called on industry leader,

Custom Ice Inc. of Burlington, Ontario.

“I got a call from Molson’s ice maker

and thought he was crazy,” said Brendan

Lenko, president and chief engineer of

Custom Ice. At first they wanted to do

a full size rink, but when the ice maker,

BJ Gagnon of Smart Ice Inc., said the

building would only fit a 42-foot by 100-

foot rink, Lenko started to listen. Gagnon

would not reveal the customer, but

assured Lenko the project was for real.

Immediately Lenko said, “You gotta

keep the pucks in with full raised netting,”

but Gagnon and Molson engineers

already had that covered. It involved tentstyle

netting supported by two columns

and a main cable running down the middle.

The netting would be installed and

removed regularly when the wind loads

required it — but the net covered the

rink completely with no puck mishaps.

Custom Ice provided the NHL-approved

netting which they obtained from ORFA

member Pro Nets Sports.

Next was the access to the roof: “How

big is the freight elevator?” Lenko asked

Gagnon. But the elevator did not go

to the roof. Helicopter? Not this time.

Fortunately, Molson had already receivedapproval from PCL to use the crane that

was erecting the building right next

door to the 120 Adelaide St. rink location.

How else could you get a 4,200

square-foot rink, boards, platform, and

refrigeration equipment to the top of a

32-story skyscraper?

A Challenging Build

PCL could only provide the crane for

two days: one day for the platform, two

weeks before the install and the other

day for all the rink equipment. With limited

roof space, every component had

to be orchestrated in sequence like a

Broadway musical production. “We just

could not box ourselves in,” said Lenko,

whose company supplied more two

truck-loads of rink equipment. It had to

fit like a puzzle even before the rink was

built and Custom Ice put together the

puzzle perfectly.

The platform, insulation, piping and

boards were all installed in one day. With

the high winds 32 stories up, Molson

engineers would not allow the platform

to just rest on the roof without enough

weight on it to hold it down. The roof was

sloped, with a waterproof membrane so they could not fasten through it. The

entire leveling platform and rink was just

resting on the roof without any anchoring.

It needed the weight to prevent the

high winds from picking it up like a sail,

so once the rink was ready it was turned

on and flooded immediately.

Once the ice was made, Custom Ice

installed the mullions and the plexiglass.

“It was a bit scary installing the glass

on the edge of the building wall,” said

Lenko. “If you drop something it could

fall 32 stories.” This was pretty dangerous.

Lenko insisted they use three crew

members to install each sheet of four-foot

plexiglass. Although it was easy to lift by

hand, Lenko’s team used suction cups

to make sure they maintained control

of the glass in the wind. Finally, a safety

cable was tightly wrapped behind the

mullions to give them extra strength

against the wind.

Lenko admitted that they underestimated

the high winds, which gusted

to 80 and 90 kilometres per hour at

times. The boards were frozen in place

in the ice and when the glass went up,

there was a much greater torque on the

freeze in place board brackets. There were a couple of close calls, but Lenko,

an engineer himself, was satisfied with

the performance.

So this is all for what? Not just a 30-second

beer commercial on Hockey Night in

Canada. There was great interest in the

rink when Toronto office workers came

back from Christmas vacation and saw

that a rink appeared when they looked

down on a neighboring skyscraper. No

one knew where it came from until

Gagnon and the ice makers put the

Molson logo down. It created lots of hype.

Because of the interest and great success

of the rink, Molson extended the

operation and offered the rink to corporate

events and individual rentals.

One hour of rooftop ice cost any group

$2,000 and a three-hour corporate event

complete with catering and the works

cost $15,000. Of course, at those prices,

Molson included a couple of Canadian

beers for each skater.

“We wanted to do a great job for

Molson,” Lenko said. “It was a once in

a lifetime event for those that skated on

the roof, but it was just as important to

our company and our staff.” Custom

Ice had their own corporate skate on

the roof on its last night of operation.

“Although we’ve built over 500 rinks, this

one was special,” Lenko added. “It was

absolutely majestic skating on the roof

top rink under a quiet star filled sky. This

one will be remembered.”

Brendan Lenko, P.Eng., is president

of Custom Ice Inc. He can be reached

at blenko@customicerinks.com or

www.customicerinks.com or by phone at

(905) 220-2580.